Editor's Note: The images in this blog are all real bill sheets audited by Kermit. For the purposes of this blog post, information has been redacted and anonymized. However, all dollar figures, including savings, remain unchanged.

If you were to design a system to manage a complex and significant expense category like medical implants and devices, it probably wouldn’t be a manual, paper-based process that gives control to commission-based sale reps. And yet, the current process is designed exactly this way and to further complicate matters, the vendor rep is present in your operating room potentially influencing the products being used.

Nobody contests that this is an archaic and flawed process where hospitals are being routinely overcharged. Kermit’s direct experience with reviewing bills in this category have verified this amount is between 5 and 10% of annual spend.

The process of auditing vendor bill sheets is complex. Multiple pricing files, volumes of contract terms and are a myriad of tricks and schemes that savvy vendor reps employ to avoid detection are significant obstacles to overcome.

We’ve provided four unique examples of inflated bill sheets that were identified by Kermit’s technology and resolved by one of Kermit’s clinical review specialists resulting in savings totaling $40,000 for our client hospitals.

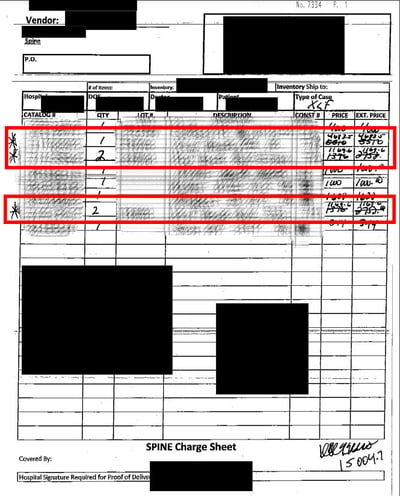

Supplier Bill #1: Items Not on Contract

| Vendor Billed Amount: | $14,282 |

| Kermit Corrected Amount: | $0 |

| Savings: | $14,282 |

Non-contracted items used in surgery are a common reason for inflated spend. Whether the use of the item is an unanticipated need during surgery by a physician or an intentional attempt to increase the vendor’s revenue, these instances add time to the vendor payment reconciliation and can impact revenue cycle with delays in patient billing.

Non-contracted items used in surgery are a common reason for inflated spend. Whether the use of the item is an unanticipated need during surgery by a physician or an intentional attempt to increase the vendor’s revenue, these instances add time to the vendor payment reconciliation and can impact revenue cycle with delays in patient billing.

In the depicted actual example, the total of non-contracted items is $14,282.

In some cases, hospitals have determined that non-contracted items will not be paid to the vendor. However, this approach can lead to further invoice discrepancies as vendors place the blame with the surgeon and remit full-value invoices regardless of any agreement. Not paying for these items can also introduce financial risk for the hospital as a tedious and manual process is employed to remove the items from the patient bill.

Kermit uses a rules-based engine to automatically determine and apply the agreed price from your corporate contract. If you wish to outsource your bid and negotiation to Kermit, our subject matter experts will ensure that industry best practices and the latest trends in PPI contracting are part of your final agreements.

Disposition: This bill was automatically corrected based on the hospital’s contract of no-charge non-contracted items.

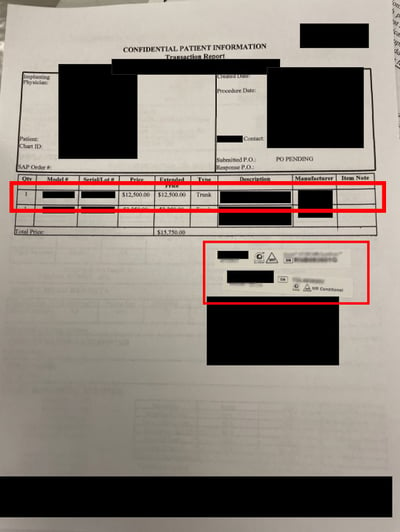

Supplier Bill #2: Incorrect Components Used

| Vendor Billed Amount: | $15,750 |

| Kermit Corrected Amount: | $7,050 |

| Savings: | $8,700 |

When reviewing bill sheets, the details matter. Some are obvious while others are a bit more hidden.

When reviewing bill sheets, the details matter. Some are obvious while others are a bit more hidden.

This supplier bill demonstrates why the details matter. This cardiovascular rhythm management (CRM) procedure has just two items used: a pacemaker and a lead. However, a major mistake inflated this procedure by $8,700.

The supplier bill is comprised of line items used and product barcode stickers from the item packaging. In this case, the line-item model, description and price did not match the sticker of the implanted item. the line item (invoiced) item is more than double the cost of the actual implanted item.

Whether by mistake or intentional, this error can easily go undetected and usually does.

Disposition: Kermit’s automation caught the discrepancy between what was billed and what was used and corrected the total. The hospital logged into Kermit to review the adjustment and issued a purchase order to the supplier for the corrected amount. Kermit transmitted the purchase order information to the supplier, along with the corrected bill and a description of adjustments so there would be no confusion on the lower-than-expected purchase order amount.

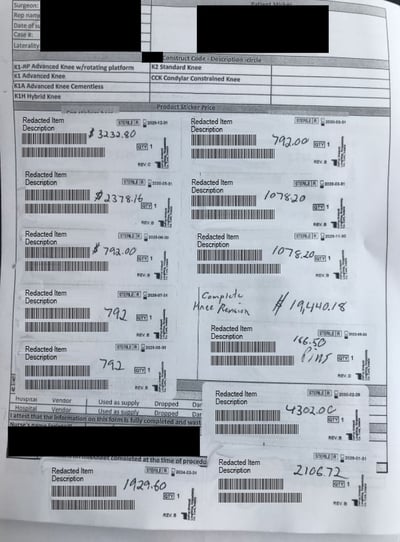

Supplier Bill #2: Incorrect Components Used

| Vendor Billed Amount: | $25,940.18 |

| Kermit Corrected Amount: | $13,933.28 |

| Savings: | $12,006.90 |

Hospital and health systems wisely use a capitated price for a construct of items, such as a total knee or hip. This approach caps the price of the procedure, regardless of the number or variety of items used and is an effective way of reducing cost and managing spend. It is also a frequently tried-and-abandoned contracting method; not because it doesn’t work, but because it can be difficult to administer without a purpose-built technology.

Hospital and health systems wisely use a capitated price for a construct of items, such as a total knee or hip. This approach caps the price of the procedure, regardless of the number or variety of items used and is an effective way of reducing cost and managing spend. It is also a frequently tried-and-abandoned contracting method; not because it doesn’t work, but because it can be difficult to administer without a purpose-built technology.

Suppliers also use this contracting method to break the construct through technical explanation, arguing that the surgeon demanded a particular item. The supplier uses a narrow interpretation in a potentially vague agreement to ignore the capitated price and, instead, charge for all items based on a line-item price.

In this example, the vendor representative supplied products for a procedure covered by a cap construct. The supplied bill sheet shows the rep attempted to bill for each item individually for a total cost of $19,440. In addition, the vendor submitted this bill with a selected capitated construct of a revision total knee carrying a price of $6,500, essentially billing twice for one surgery.

Disposition: Kermit’s software recognized that this case should be billed at the capitated construct queued the case for clinical audit. Kermit’s audit specialist corrected the bill, resulting in $12,006.90 savings.

Supplier Bill #4: Price Charged Higher Than the Contracted Price

| Vendor Billed Amount: | $18,234.00 |

| Kermit Corrected Amount: | $9,986.52 |

| Savings: | $8,247.48 |

.jpg?width=400&name=Bill%20Sheet%206%20(1).jpg) One of the most obvious examples of inflated bill sheets can be traced to vendor reps handwriting a price that is higher than contracted price for individual items. It is difficult to manually check every item and, most times, buyers spot-check high-dollar items and anomalies.

One of the most obvious examples of inflated bill sheets can be traced to vendor reps handwriting a price that is higher than contracted price for individual items. It is difficult to manually check every item and, most times, buyers spot-check high-dollar items and anomalies.

Errors, whether overt or covert, add up and can result in considerable overcharges which are then paid and go undetected. On this vendor bill, a primary robotic-assisted total knee was billed as line items, which was the correct approach.

However, in every billed item the vendor got it wrong and billed an amount higher than contracted.

Disposition: Kermit’s audit capabilities immediately compared each billed catalog number with the approved price contracted at this hospital and efficiently reconciled all eleven items to their correct price resulting in over $8,200 in savings and an approved price of $9,986; a correction of over 50% to the supplier’s billed amount.

How Kermit Can Audit Your Bill Sheets and Find Thousands in Savings

Kermit’s software, the only one of its kind, is designed to catch implant supplier bill inaccuracies, enforce your contract pricing and terms, and free your valuable staff to address other pressing matters. Kermit is the only technology-enabled solution available today collecting data at the point of use, correctly categorizing implants used, automating the review all supported by medical device and hospital contracting veterans.

To learn more about how Kermit can strengthen your bill sheet process, fill out the form below to schedule a quick meeting: